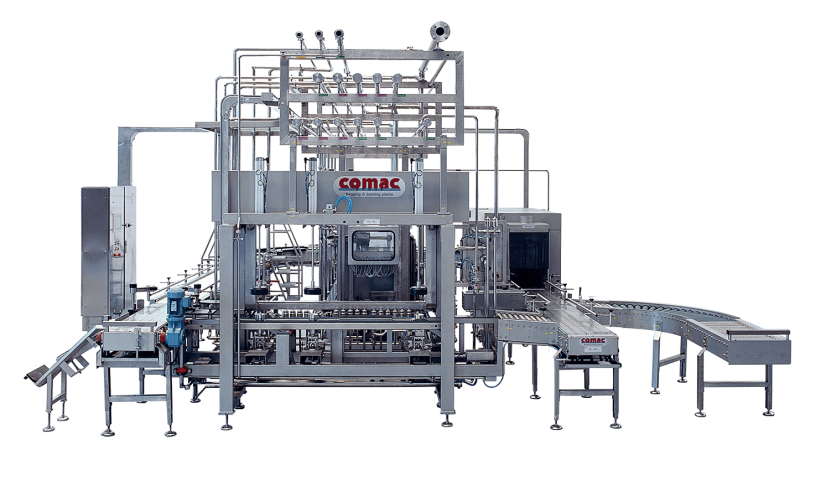

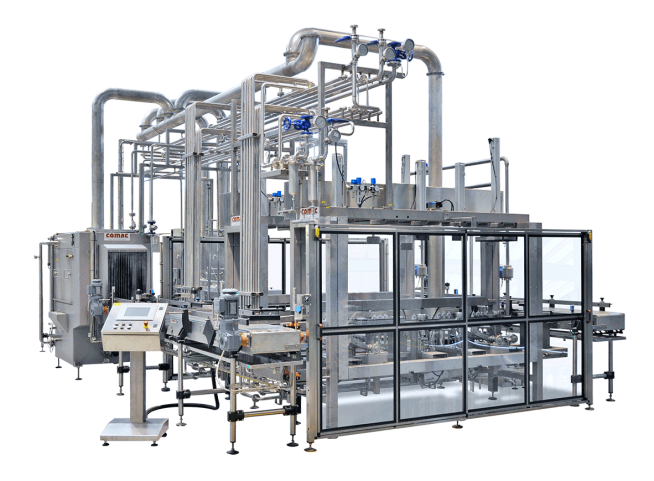

Automatic and semi automatic keg lines for the processing and packaging of beverages in kegs of any size. Our kegging systems are made favoring the technical specific customers’ requirements, choosing between the best available solutions in the wide range of machines that Co.Mac. produces.

Our kegging systems are divided into three categories:

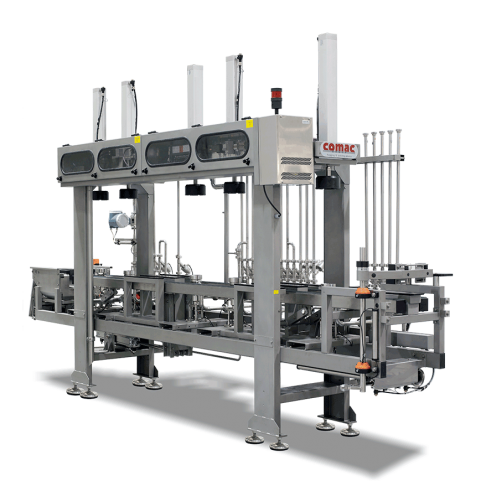

- semiautomatic systems for productions from 15 to 40 kegs/hour, suitable for microbreweries;

- automatic systems for productions ranging from 40 to 250 kegs/hour, suitable for medium breweries;

- automatic systems for productions over 250 kegs/hour, suitable for big industries.

All the advantages of a Co.Mac’s kegs filler

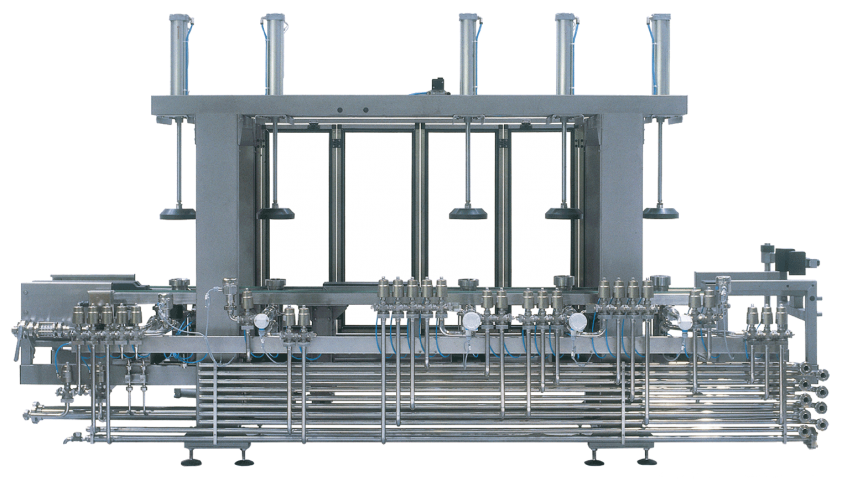

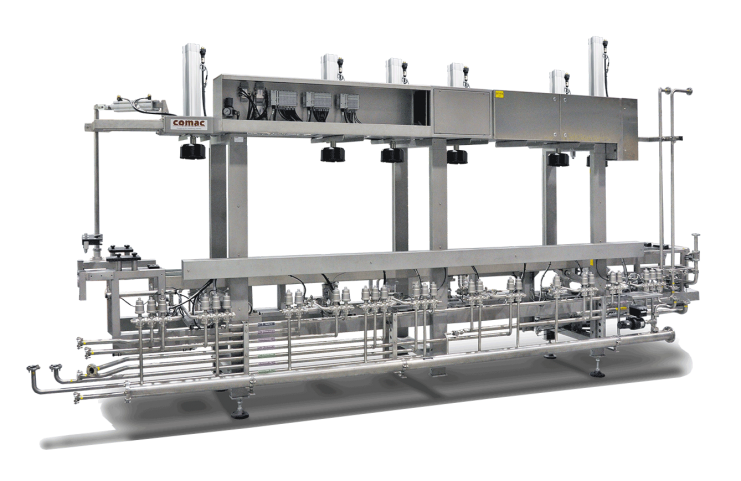

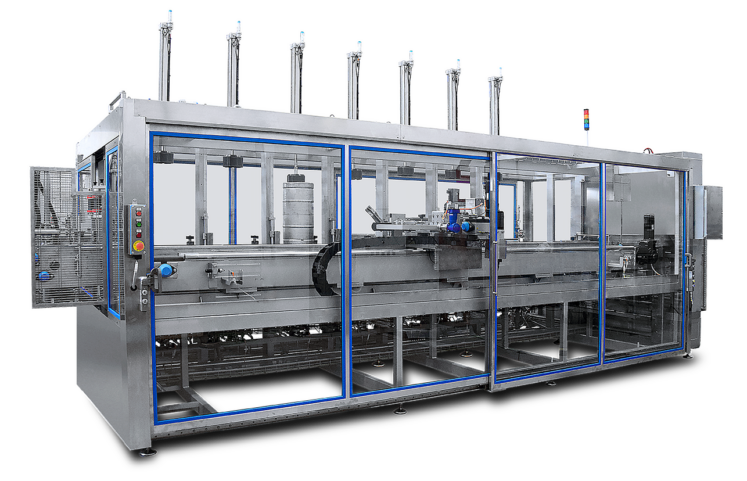

Our keg lines are designed for stainless steel kegs but can also be adapted for one-way plastic kegs. Their great efficiency and reliability are determined by:

- Thirty years of technical expertise;

- High technological level;

- Great quality of raw materials;

- Excellent usability and speed of processes;

- Possibility of customizing the kegging line.

Regarding the last point, Comac offers a wide range of auxiliary machines to achieve a more complete keg line.

Co.Mac’s beer keg lines: efficiency and versatility for small and big productions

The kegging solutions offered by Co.Mac. are ideal for the filling of various beverages, particularly beer. Designed to meet the needs of breweries of all sizes, our beer keg lines ensure maximum efficiency, hygiene, and reliability throughout the kegging process.

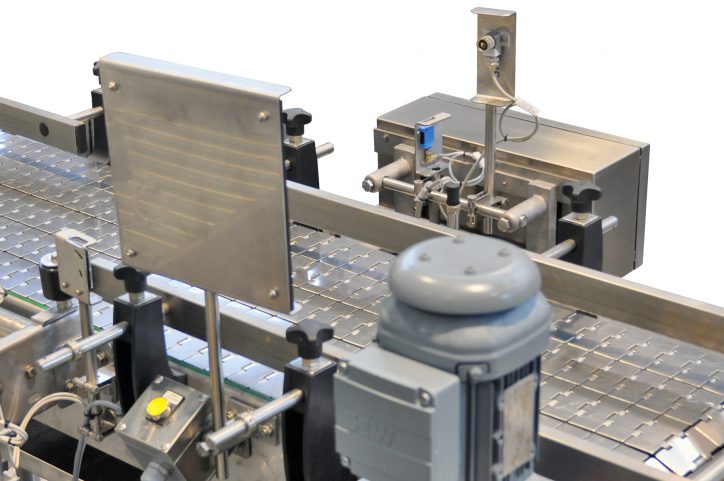

Whether you are a craft brewery or a large-scale producer, our systems are customizable to handle different production capacities while maintaining the highest standards of quality. From washing and filling to sealing and monitoring, Co.Mac. beer keg lines are equipped with cutting-edge technology to optimize operations and guarantee exceptional results.

Our ancillary machines for your keg filling line

Our ancillary machines for kegs can be grouped in this way:

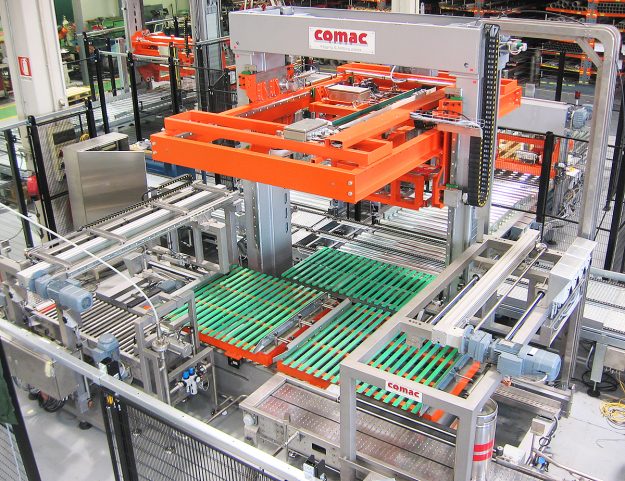

- Automatic machines for start and end of line like palletizers and depalletizers, automatic warehousing solutions, pallet centering devices, pallet stackers and destackers;

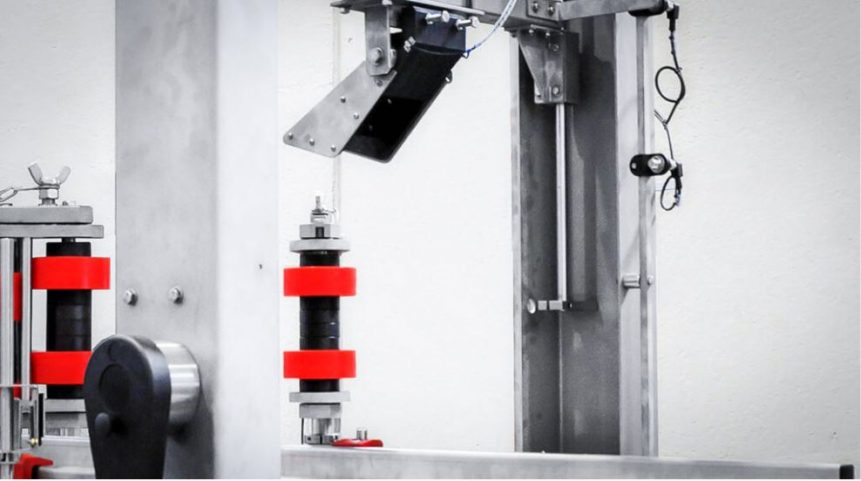

- Kegs control stations such as keg integrity, inspection and fitting stations, weighing machines and temperature stations;

- Keg turners and washers;

- Collar application and extraction system;

- Keg cappers and decappers.

Thanks to all these machines, it is possible to have a constant control of the keg during each and every filling step.

Choose Co.Mac. for your keg line

In addition to the wide range of equipment and accessory machines available, Comac is the best choice for installing your keg filling line for other reasons as well:

- We provide a 24h/24h technical support in order to be always available when needed;

- You can rely on our Customer Care service: our team is always ready to solve any problem in the shortest possible time;

- We can assist you wherever you are, thanks to our remote assistance via webcam;

- We provide spare parts for your machines and technical upgrades of the systems.