To improve its business processes, Co.Mac has been employing Lean production practices for several years now.

The ultimate goal of this method is to eliminate all kind of wastage (not only of material, but also time, costs and skills) in order to guarantee maximum efficiency and improve responsiveness to customers’ needs.

Since it entered the ATS Corporation group, Co.Mac has been increasing its efforts in this direction, and has adopted the business system that has been guiding the disciplined and continuous improvement processes of the entire group since 2017: ABM (acronym for ATS Business Model).

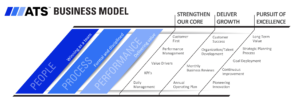

The ABM model leverages three keywords: People, Process, Performance and is constantly applied through all departments by means of both single events (such as Kaizen days) and continuous processes, such as the adoption of visual management and on-the-job and classroom training courses.

People: our foundation

“The foundation of a great business is having great people. It follows, then, that working to develop, engage, empower and energize our people is both a core ATS value and the first of our three pillars, followed by process, and then performance, at the foundation of the ABM”. – Andrew Hider, CEO

The energy and empowerment of the people who work in the ATS Group is key to making impactful and continuous changes. For this reason, training courses and Kaizen events play an important role in detecting and trying to solve waste issues, identifying appropriate solutions with a dedicated team.

Processes: a culture of continuous improvement

“At its core, our ABM is our pursuit of continuous improvement in everything we do. If we have a standard process, and we can measure that process, we are capable of driving sustainable improvements”. – Jeremy Patten, VP ATS Business Model.

The ABM model cuts across all business functions and is deployed across three phases to achieve three goals: strengthen our core, deliver growth, and pursuit of excellence.

Performance: for employees, customers and shareholders

“After the Kaizen event, I am amazed at the results we delivered in just one week. Please keep driving the ABM throughout the business” – Production Team Leader, Cambridge Life Science Division

The current and future performance of Comac and of the entire ATS group depends on this relentless process of growth, which brings benefits to all those who, in various ways, work with us: employees, suppliers, customers.

ABM Award 2024 - Most Improved Site

Award presented to Co.Mac during the ATS Leadership Conference 2024 as the company in the group that achieved the greatest improvement in the past year.