Weighing machines

Overview

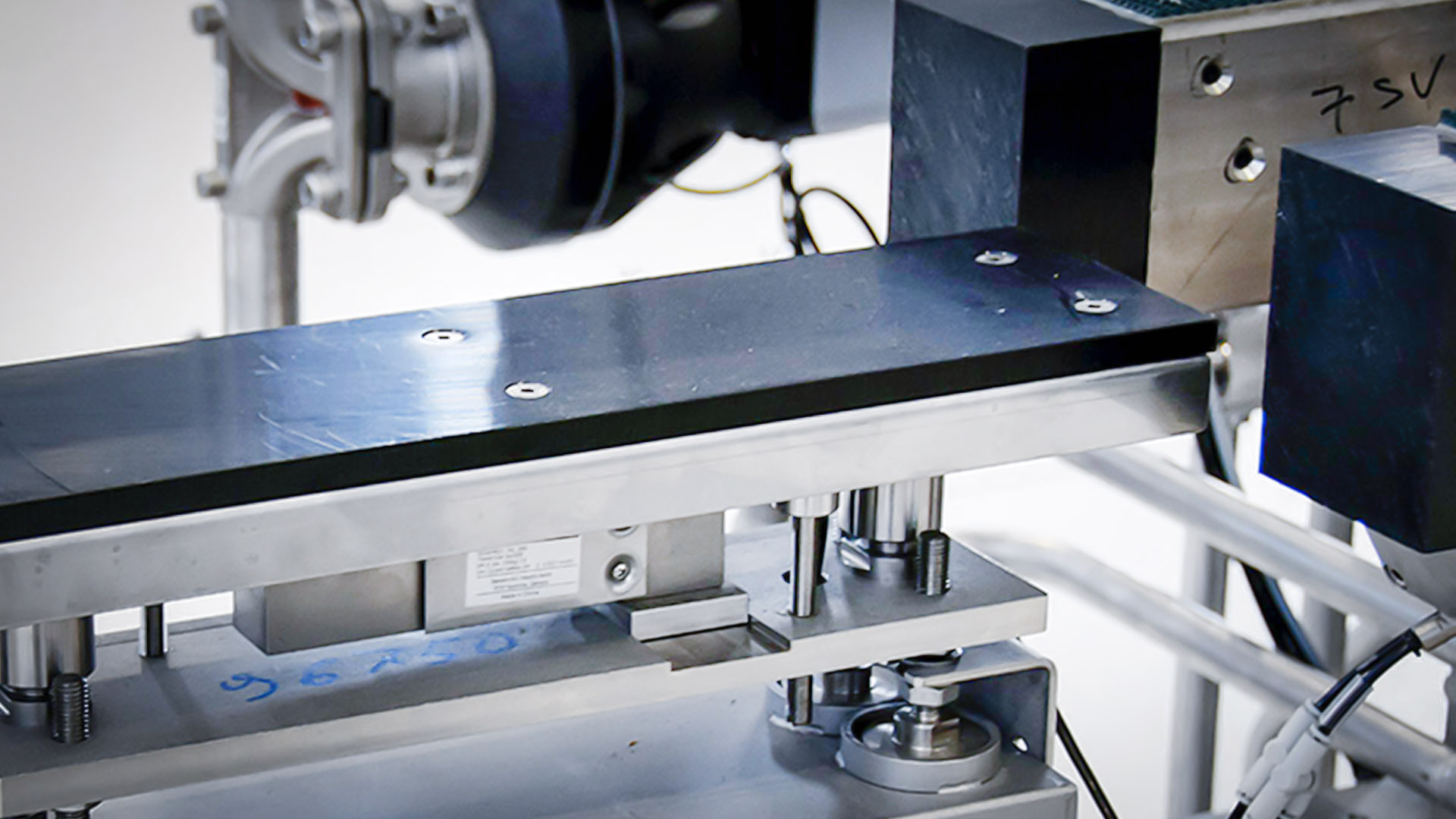

The static weighers are installed onto the walking-beam washers/fillers, to check the weight of the kegs after filling and eventually also the tare, to compare the weights of empty and full kegs and to discard the kegs that have not been filled correctly, or that contain an inaccurate volume of beer.

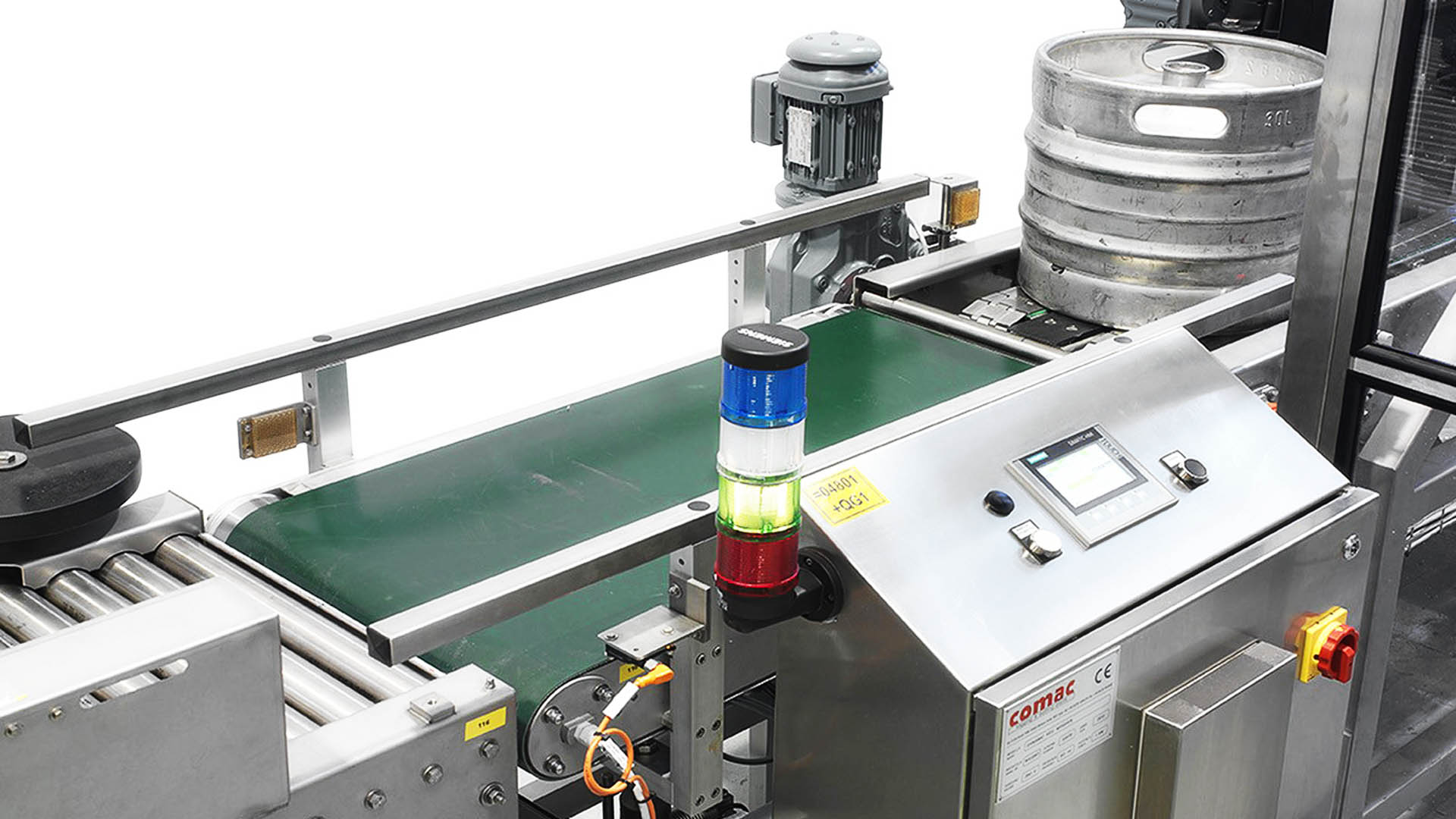

In medium to high-speed keg lines where there are several keg washers/fillers, the static weighers are usually replaced by a dynamic weigher, installed on the conveyor belts downstream of the fillers. The dynamic weigher checks the weight of the full kegs as they pass on the conveyor belt, without having to stop them.

The static weighers are controlled by the PLC of the keg washer/filler, while the dynamic weighers are equipped with their own PLC and HMI, which also communicate with the PLC of the filling line.

Advantages

- Weight control of full kegs to discard empty or under-filled kegs

- Weight control of empty and full kegs to reject kegs filled with an incorrect volume of product

- Reliability in every possible line configuration

- Easy and cost-effective maintenance

- Quick and easy changeover operations (selection of the correct recipe in the HMI)

Products

- Beer

- Still and sparkling wine

- Carbonated soft drinks

Formats

- Kegs