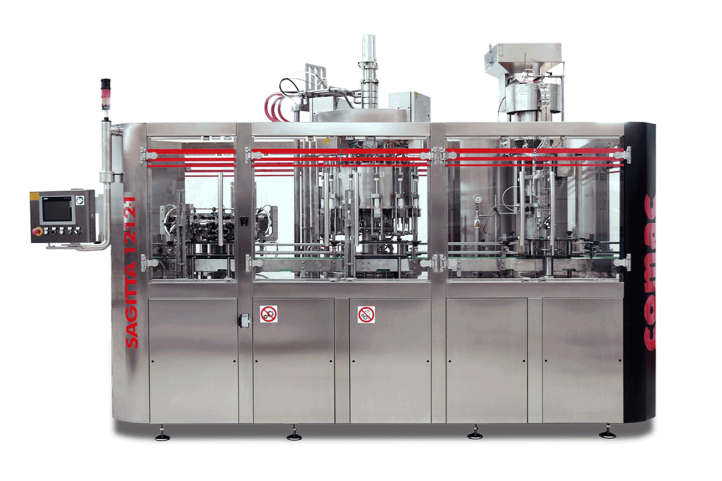

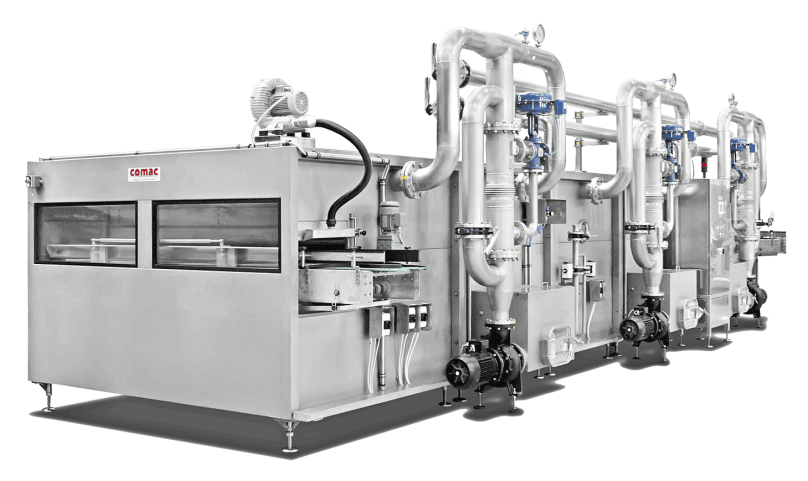

Automatic bottling systems for processing and packaging bottled beverages of any size: bottling lines are made complying with the technical requirements of the customers, choosing between the best and available solutions in the wide range of machines that Co.Mac produces.

Co.Mac provides bottling plants and equipment for worldwide companies of all kinds and dimensions, creating customized solutions for any product to bottle.