Non-Alcoholic Beer Production: Processes and Solutions

In recent years, non-alcoholic beer has been gaining popularity due to a growing demand for healthier alternatives to traditional beverages. This article explores the production of non-alcoholic beer and what Co.Mac can offer for safe and quality packaging.

In this article:

- How non-alcoholic beer is produced

- What happens after production

- Packing your non-alcoholic beer with Co.Mac

How Non-Alcoholic Beer is Produced

Non-alcoholic beer production is based on two main criteria: the first foresees removing alcohol at the end of the production process, while the second prevents alcohol formation during fermentation.

Removal of alcohol at the end of the process

The first method can be achieved through two main techniques:

- Vacuum distillation: in this case, beer is heated in a low-pressure environment to allow alcohol to evaporate at much lower temperatures than its boiling point. This allows alcohol to be removed without losing the beer’s aromatic ingredients.

- Membrane filtration with reverse osmosis: here, a specific membrane is used to retain the alcohol in the product, under high pressure.

Preventing alcohol formation during production

As for this second method, the focus is on controlling fermentation to contain alcohol production. This can be achieved in two ways:

- Inactivate yeast, once the desired alcohol level is reached

- Use of special yeasts that ferment only simple sugars, thus avoiding transformation into alcohol.

What Happens After Production

Once the production of non-alcoholic beer is completed, the next step is packaging; the best options for filling include cans, kegs, and bottles, each with its specific advantages.

Cans, for example, are excellent for impeding light, that can quickly degrade beer. Kegs, on the other hand, are ideal for large-scale distribution, especially in settings such as bars and restaurants.

Lastly, bottles: not only do ensure a high degree of sterility but also offer added value, aesthetically speaking.

Unsure which type of filling is suitable for your non-alcoholic beer? Co.Mac is here to help!

The Importance of Pasteurization for Non-Alcoholic Beer

Pasteurization plays a fundamental role in maintaining the quality of non-alcoholic beer.

Since it is an alcohol-free product, with alcohol considered as a natural preservative, pasteurization becomes a fundamental step in the non-alcoholic beer production process, as this allows a longer shelf life.

This phase consists in bringing the beer to pasteurization temperature for a given period of time, in order to eliminate most of the bacteria and micro-organisms, which could alter its quality.

In addition to the traditional range of pasteurizers, for some years Co.mac has introduced a smart line of variable-flow flash pasteurizers. Available in two sizes, 1,000/2,000 L and 2,000/4,000 L, these machines can be set up for the pasteurization of non-alcoholic beer by appropriately sizing the tubular thermal unit, to keep the product at temperature for the time necessary to obtain the correct number of PU, which generally is much higher than the number of PU required for beers with alcohol.

Packing Your Non-Alcoholic Beer with Co.Mac

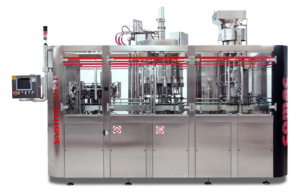

Co.Mac stands out in the market for its innovative processing and filling solutions, suitable for non-alcoholic beer as well.

A range that adapts to different production volumes, from small craft productions to large industrial realities, Co.Mac can meet the requirements of every customer.

Our solutions for filling kegs, cans, and bottles not only guarantee precision and efficiency but also remarkable versatility.

Keg Filling

For keg filling, Co.Mac offers semi-automatic and automatic plants, suitable for productions from 15 to 1,200 kegs per hour. These systems can be customized to process both stainless steel kegs and one-way and BIB kegs, ensuring flexibility and efficiency. Advanced technology and the quality of raw materials ensure reliability of the plants and yield optimization, simplifying changeover operations.

Picture: HIVE model (up to 18 kegs/hour) and Bergamo model (from 270 kegs/hour)

Need further information?

Can Filling

For can filling, including filling with non-alcoholic beer, Co.Mac range includes automatic systems ranging from 3,000 to 12,000 cans per hour. For higher productions, we collaborate with CFT Group for optimal performance up to 70,000 cans per hour.

Like all our plants, can lines as well can be customized according to customers’ requirements and complemented by auxiliary machines to manage every phase of the production process.

Picture: model Pegasus 8-1 V2 (up to 4,000 cans/hour) and Microbrew 20-4 (up to 12,000 cans/hour)

Bottle Filling

Co.Mac can also offer automatic plants for non-alcoholic beer packaging in glass bottles. These systems can handle productions from 2,500 to 6,000 bottles per hour. For higher productions, up to 70,000 bottles per hour, we collaborate with the CFT group. Bottling lines, like those for cans, are suitable for beer, wine, alcoholic and non-alcoholic beverages, and water.

Picture: model Sagitta 12-12-1 P (up to 3,000 bottles/hour)

Contact us to learn more about our solutions for non-alcoholic beer!