Why Choosing a Beer Keg Filling System?

A keg filling system for beer packaging may turn out to be particularly advantageous if manufactured with high-quality materials and cutting-edge technologies, just like the solutions offered at Comac.

In this article:

- Beer keg filling systems from Comac

- Some models from the range

- The advantages of a beer keg filling system

Beer keg filling systems from Comac

Comac specializes in manufacturing various types of beer keg filling systems of the highest quality, meeting the requirements of breweries of different sizes, from craft breweries to the industrial and multinational ones.

Specifically, Comac range includes:

- Semi automatic filling systems that deliver 15 to 40 kegs/hour, particularly suitable for microbreweries and small-sized businesses

- Automatic filling systems that deliver 40 to 250 kegs/hour for breweries with higher production capacity

- Automatic filling systems that deliver 250 to 1,000 kegs/hour for businesses requiring high production rates

Along with the possibility of adapting the plants according to a customer’s business size, keg filling systems from Comac stand out for their:

- Versatility, which makes it possible for them to both treat stainless steel and one-way plastic kegs

- High technical know-how and technology, which characterize designing and manufacturing steps in order to guarantee the utmost efficiency

- Quality of raw materials used, capable of ensuring that the beer has an excellent quality standard and its taste is not altered

Some models from our range

As already mentioned, Comac offers different solutions for keg filling, which are perfect not only for beer but also for other alcoholic and non-alcoholic beverages. Let’s see a few recommendations:

HIVE – for stainless steel and plastic (one-way) kegs is able to fill up to 18 stainless steel kegs/hour and up to 45 plastic one-way kegs/hour. This solution is ideal for small businesses. Its structure is composed of a single filling head and a tank for detergent solution storage. This model is robust, user-friendly, and particularly easy to install, connect, and use. Safety and hygiene are guaranteed.

Smart Kegging Machine – K2 is part of semi automatic keg filling systems and is designed and manufactured to meet the requirements of small and medium-sized businesses. This version has a maximum production capacity of 36 kegs/hour and consists of two heads: one for washing and the other for filling. It can also have up to three tanks for detergent solution storage.

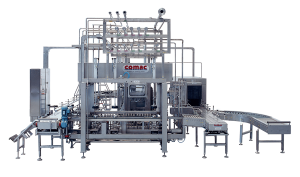

Our automatic plant range (in the picture: our Capri K31 – 3+1T model) includes several models with a production yield of 40 to 90 kegs/hour. Each machine automatically carries out the washing and keg filling cycles. Along with beer, these plants can perfectly treat other beverages such as cider, still and sparkling water, soft drinks, and wine. They are also equipped with a PLC and an HMI operator panel that facilitate the user when setting up and checking all the operation parameters.

Bergamo HS6T is a modular beer keg filling system that can fully automatically deliver the pre-washing, washing, and filling operations. It is designed for keg lines with very high production requirements. Each one of its modules (pre-washing, washing, and filling) is equipped with six treatment heads and is made with AISI 304 stainless steel, which guarantees hygiene and safety.

Find out more about our beer keg filling systems!

The advantages of a keg filling system

Choosing a keg filling system designed by Comac means:

- Efficiency, due to the possibility of choosing the plant according to your production needs

- Very long service life, due to the excellent materials used in its manufacturing

- Hygiene, because our filling systems are designed to avoid any beer contamination and thus the risks concerning the safety of the consumer and the quality of the beverage

- Control: each system performs every step of the process, from keg pre-washing to keg filling

- Adaptability: each machine can be easily combined with other additional machines designed by Comac in order to obtain a filling line that is even more complete and efficient.

Choose the true experts in beer packaging. Choose Comac!