Optimizing Production Costs in Breweries

Optimizing production costs in breweries is a process that involves technical, organizational, and equipment-related decisions, with direct impacts on efficiency, final product quality, and production scalability. The entire chain must be supported by systems designed to minimize waste, increase production continuity, and maintain control over critical parameters such as energy consumption, temperature, and product loss.

Before developing a cost-optimization strategy, it is essential to analyze the layout, the level of automation, expected volumes, and the quality standards required.

In this technical discussion, intended for plant directors and production managers, we will examine the primary cost drivers in a brewery and the opportunities offered by automation to reduce waste and downtime.

Additionally, we will illustrate how Co.Mac., a global leader in the engineering of filling and packaging lines for kegs, cans, and glass bottles, is actively supporting breweries in reducing production costs.

The objective of this article is twofold: on one hand, to provide a comprehensive overview of cost-related challenges in brewing operations; and on the other, to demonstrate how Co.Mac.’s solutions can improve operational efficiency, line reliability and overall economic sustainability.

Brewery Cost Structure

The operational costs of a brewery are influenced not only by beer production itself, but also by the performance of the packaging lines. It is within the stages of transfer, filling, seaming, and packaging handling that many inefficiencies arise, affecting both OEE (Overall Equipment Effectiveness) and final cost per liter.

Key cost contributors include machine energy consumption, product waste due to suboptimal filling, losses caused by defective packaging, and downtime triggered by failures or component wear. Water and detergents used for CIP (Cleaning-In-Place) cycles on filling systems also represent a significant cost factor, especially in breweries processing large packaging volumes.

What are the critical aspects that must be closely monitored to avoid losses and waste?

One of the most sensitive areas is product control during filling and sealing. Excess dissolved oxygen, overfilling, or mechanical instability can lead to substantial product discard. Optimizing brewery costs therefore depends on using high-precision valves, pressure sensors, and inline monitoring systems to minimize waste and ensure consistent and repeatable results.

Maintenance also plays a crucial role: equipment equipped with vibration, temperature, and load sensors enables predictive interventions that drastically reduce unplanned downtime, preserving production continuity. Parallel to this, automation of quality checks, from keg testing to pallet integrity verification, makes it possible to detect anomalies before they evolve into actual waste.

Finally, packaging handling directly influences overall costs. Optimized conveyors, correctly calibrated diverters, and engineered twist-guides reduce the risk of drops, jams, or tipping, ensuring smoother flow and fewer operational losses.

In conclusion, an integrated management approach to these factors yields a realistic picture of inefficiencies and identifies precisely where corrective action will result in measurable and tangible cost savings.

Waste Reduction Through Automation on Can Lines

Automation is one of the most impactful levers for reducing waste in a brewery.

The implementation of advanced technologies in filling, handling, and quality control minimizes product loss, reduces reject rates due to container defects, and maintains high OEE across the line.

For canning lines, Co.Mac. offers the Microbrew 10-2 and Microbrew 20-4 monoblocks, two models designed to incorporate solutions tailored to optimize filling and seaming.

Key elements include:

Electropneumatic Filling Valves

Shifting from gravity to electropneumatic isobaric filling represents a major technological upgrade in waste reduction. The Microbrew monoblocks’ valves ensure extremely precise volume control, significantly reducing product loss relative to entry-level systems. This eliminates both underfills and overfills, preventing unnecessary packaging waste from non-conforming cans.

Result: lower unit cost and improved profitability per packaged liter.

No-screw Format Change System

Format changeover has traditionally been one of the most time-consuming stages for breweries handling multiple formats. The Microbrew series uses an operator-friendly infeed system that allows format changeovers quickly and without special tools, reducing setup times and cutting labor-dependent costs.

Result: less downtime and a more stable OEE.

Microbrew Smart Gate

Smart Gate is one of the most effective solutions for preventing waste caused by temporarily inactive filling valves. When one or more valves are excluded from production, the intelligent gate automatically stops cans that would otherwise be positioned beneath them.

Benefits: prevents waste of cans, lids, and product; allows the line to continue running, even at reduced speed, until the issue is resolved. This is particularly advantageous when replacement parts are not immediately available.

Multispectral Camera for Foreign Bodies and Flange Deformation

To further reduce rejects and protect the filler, a high-resolution inspection station can be integrated. The system compares each can to a reference profile using artificial intelligence, automatically rejecting those with deformation, flange ovalization, or possible foreign objects.

Conveyor Bearings

Maintenance represents a frequently underestimated cost item. The use of foam-lubricated hygienic bearings eliminates lubrication requirements entirely.

Benefits: drastically reduced maintenance costs, zero risk of lubricant contamination, and no scheduled lubrication-related downtime.

BOD – Blow Off Device

To improve safety and optimize energy consumption in packaging areas, the BOD system allows separate discharge of liquid and gas from the monoblock.

Benefits: by venting CO₂ outside the facility, operator safety is improved and the need for ventilation is reduced—lowering energy costs and improving environmental comfort.

Illuminate™ Manufacturing Intelligence

Last, but strategically vital, is the Illuminate™ platform. This intelligent monitoring system analyzes real-time line data, providing operational insights based on OEE, valve performance, component degradation, and generated waste.

Benefits: early detection of anomalies enables intervention before inefficiencies arise, reducing energy loss and product waste while increasing overall productivity. Illuminate is a stepping-stone toward integrated plant management, as discussed in the next section.

Waste Reduction via Automation for Keg Filling Operations

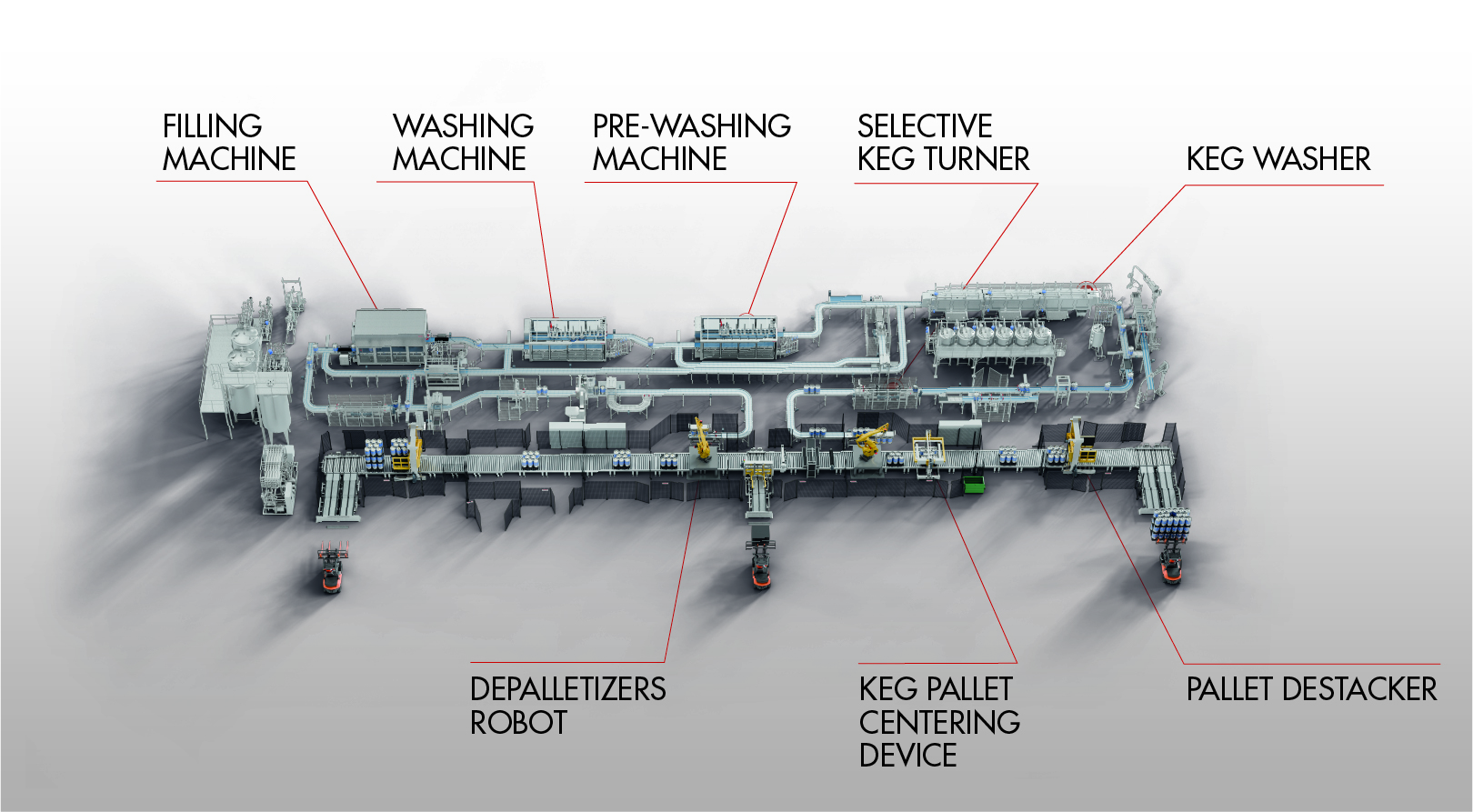

Cost optimization in breweries also extends upstream of packaging, particularly in keg inspection and pallet handling. If not properly controlled, these stages can generate product waste, unnecessary consumption, equipment damage, and unplanned downtime—directly impacting OEE and overall operating cost. Co.Mac.’s technologies are engineered to detect failures before they translate into inefficiency.

Keg Inspection Systems

The tools integrated into Co.Mac. keg lines rapidly identify anomalies before filling. The system verifies multiple critical parameters:

- Macro-leaks and micro-leaks detected via automatic CO₂ leakage stations

- Temperature, measured by non-contact pyrometer to detect out-of-spec kegs

- Residual pressure, measured by inspection heads to reject returned kegs that do not meet pressure requirements

- Structural integrity of keg body and fitting to detect damage affecting filling reliability

- Weight, monitored by static or dynamic scales to detect incorrect fills

Identifying a non-conforming keg before starting the cycle prevents wasted production time, product loss, and unnecessary energy and material consumption. For a brewery, this results in immediate cost reductions and greater process reliability—particularly for high-volume or continuous-shift operations.

Pallet Integrity Control System

Pallet handling represents another major operational risk. Broken, deformed, or out-of-spec pallets can cause tipping of cans or kegs, damage to equipment, and unplanned stoppages. To address this, Co.Mac. developed PALInspect AI, a pallet integrity control system also highlighted in a dedicated technical article.

Using integrated sensors and validation logic, PALInspect AI analyzes pallet geometry and stability before entering the production cycle. Any defects or weaknesses are immediately identified and isolated, preventing damaged pallets from causing accidents, slowdowns, or product loss. The system also reduces extraordinary maintenance costs resulting from crash-related equipment damage, while improving operator safety and line stability.

The combination of keg inspection, pallet verification, and the automation technologies described earlier results in a consistent, safe, and highly efficient production flow. Every component—from the container itself to the unit transporting it—contributes to waste reduction, downtime prevention, and cost optimization across the entire packaging process.

Co.Mac.’s solutions integrate these principles into a comprehensive approach, spanning from container treatment to real-time production monitoring.

To determine which solutions are most suitable for your facility, you can explore Co.Mac.’s equipment portfolio or request a dedicated technical consultation with our specialists.