Keg transport systems: a complete technical guide

Do you design industrial plants or manage a kegging line? As you know, keg transport systems are essential to ensure operational continuity and safety at every stage of the process.

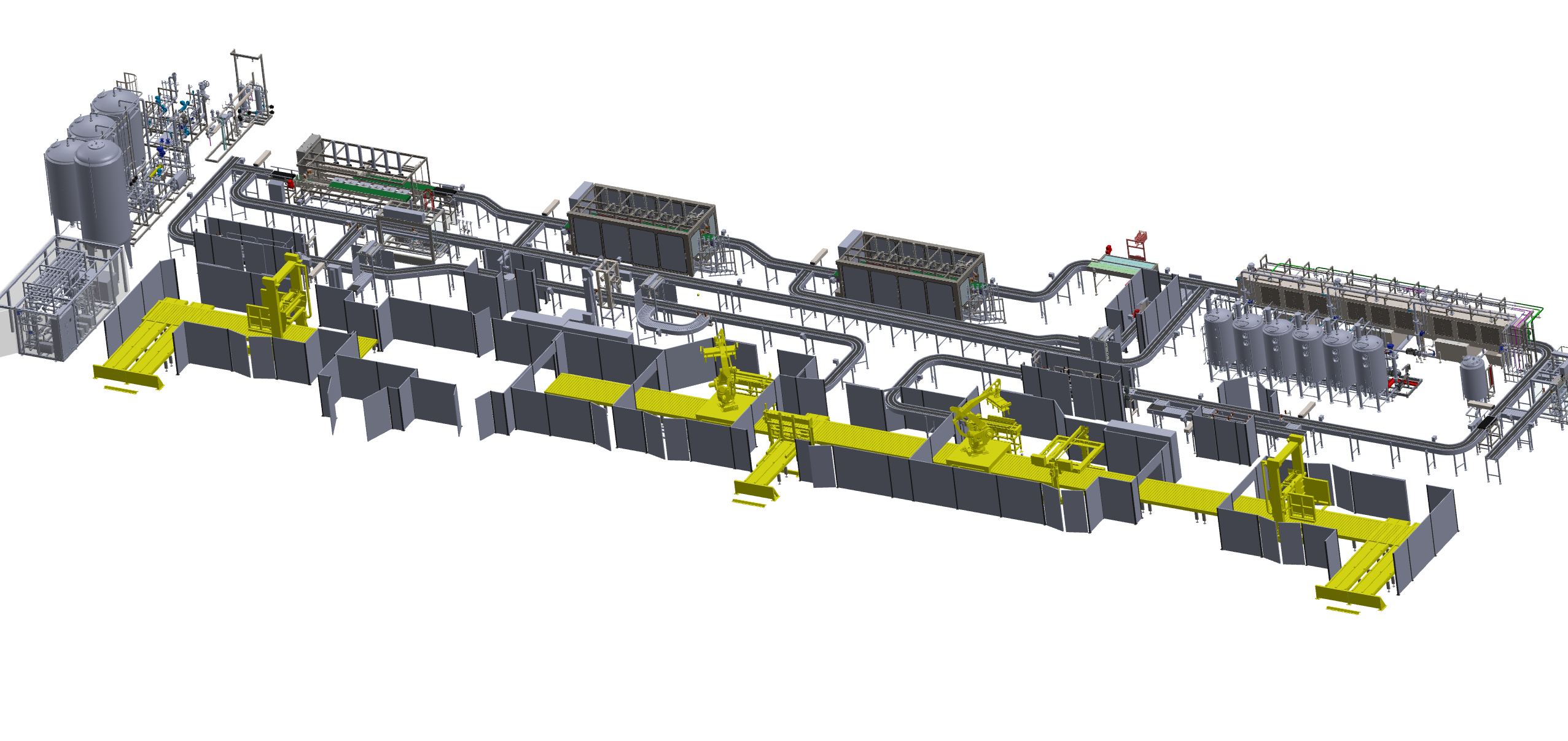

In Co.Mac. Keg Lines, conveyors efficiently connect all processing phases, from washing to filling, from storage to palletizing.

Choosing the right transport systems is a key decision for breweries, bottlers, and soft drink producers, as it directly impacts productivity, product quality, and operator safety.

That’s why it’s crucial to adopt modular, reliable, and hygiene-compliant solutions that can adapt to different keg formats and complex production layouts.

This technical guide will help you identify the keg transport systems best suited to your needs. You’ll learn:

- The main types of keg conveyors and how to choose them;

- How to design an efficient and safe layout;

- Synchronization and control solutions to optimize flow and minimize downtime.

Types of keg transport systems

Types of keg transport systems

When selecting a keg transport system, several key factors must be considered, all of which affect productivity and safety.

- Type and material of kegs: stainless steel, plastic or aluminum; empty or full;

- Weight and size: determine motor power and conveyor type;

- Path length and complexity: straight or curved sections and elevation changes;

- Working environment: presence of humidity, corrosive agents, or the need for frequent washdowns;

- Automation level required: manual, semi-automatic, or fully automated;

- Future scalability: modularity and upgrade potential.

You can choose between:

- Modular belt conveyors: ideal for plastic or aluminum kegs and straight sections. Easy to clean and highly stable.

- Motorized roller conveyors: recommended for full steel kegs, heavier loads, or accumulation zones where static load is higher.

- Chain or slat conveyors: suitable for all keg materials when the layout is complex, includes elevation changes, or requires fast movement.

In addition to horizontal conveyors, keg handling lines may include automatic elevators (for vertical transport) and keg inverters (for operations such as washing or filling). These systems improve safety and reduce manual handling.

Co.Mac. offers modular stainless steel AISI 304 conveyors, corrosion-resistant and easy to sanitize—ideal for humid environments and frequent washdowns.

Technical tip: to optimize energy consumption and reduce wear, Co.Mac. uses low-energy motors and optimized gear units combined with wet or dry automatic lubrication systems that minimize friction between the keg and conveyor. PLC-based management allows speed and sequence adjustments according to keg format and production rate.

Note: tor plants requiring modernization, Co.Mac. offers line revamping services, technology upgrades that enhance productivity and energy efficiency without replacing the entire conveyor system.

Layout types

When designing a keg transport system, key operational questions arise. What is the most efficient layout for my production space? How should flows be managed to avoid bottlenecks? Will the conveyors be expandable or modifiable in the future?

To answer these questions, it’s crucial to carefully analyze the facility structure, production volumes, and maintenance and safety needs.

Common layout configurations

- Linear: simple and efficient, perfect for compact plants where the production flow follows a direct path from loading to unloading.

- U-shaped: ideal for tight spaces where an orderly flow must be maintained; optimizes narrow surface areas while keeping processes close.

- Loop or multi-line layouts: ideal for high-volume production and complex lines, supports continuous flow and reduces stoppage risks during partial downtimes.

Pro tip: regardless of the chosen layout, always include accumulation zones between the most critical machines. These act as buffers during slowdowns, avoiding full line shutdowns.

Conveyor customization

Co.Mac. designs modular food & beverage conveyors, available in both straight and curved versions. A wide range of chains and accessories allows full customization based on keg type and environmental conditions. Thanks to their modularity, these systems are easily expandable without the need to replace the entire line.

Technical note: gear motor units are selected based on keg weight and required transport speed. Using high-efficiency motors and smart flow control software reduces energy use and chain wear, especially during accumulation phases.

Pro tip: during the design phase, always leave sufficient side aisles for maintenance and keep open zones available for future upgrades or new equipment.

Synchronization and control

In an automated keg transport line, synchronization between conveyors and processing machines is essential. Key stages (washing, filling, sealing, and palletizing) must be precisely coordinated to avoid collisions, idle times or excessive accumulation, all of which can compromise overall efficiency.

To achieve this, Co.Mac. integrates state-of-the-art PLCs (Programmable Logic Controllers) into its systems. These programmable devices ensure safe, automated management of machines and conveyors, dynamically adjusting speed, start/stop cycles, and priorities based on production flow and keg formats.

Supporting the PLCs is a network of smart sensors and real-time feedback systems that constantly monitor keg flow across the line. Conveyors adapt their speed and operation sequences to the actual load, preventing bottlenecks, overaccumulation, and critical slowdowns.

Practical advice: Implement intuitive dashboards tailored to user roles and easily readable even by non-specialist operators. This enables rapid detection and resolution of anomalies, reducing downtime and boosting overall productivity.

An additional level of control is provided by integration with MES (Manufacturing Execution Systems), which offer advanced production flow management and full keg traceability. These systems provide strategic data for quality control, predictive maintenance, and energy optimization.

To ensure long-term reliability, Co.Mac. also offers remote assistance services and periodic software updates to keep systems aligned with the latest technological advances.

Technical tip: Besides preventive maintenance contracts, schedule regular sensor testing and constantly monitor control system response times. Don’t forget to perform periodic backups of operational data to ensure business continuity in case of unexpected failures.

Conclusion

Whether you’re designing a new production line or upgrading an existing system, choosing the right keg transport solution has a direct impact on performance and product quality.

For high-output or complex applications, trust partners with proven expertise and deep industry knowledge. With over 30 years of experience and tailor-made solutions, Co.Mac. is the ideal partner to rely on.

Looking to design or improve your keg transport line? Discover all Co.Mac. Keg Lines and request a dedicated technical consultation.