Designing beverage packaging line layouts

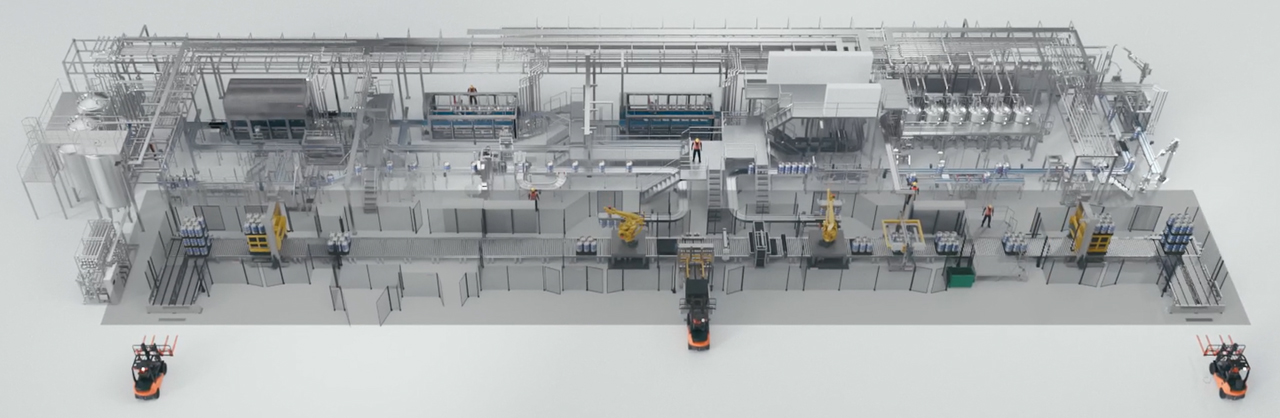

In beverage packaging facilities, the configuration of the production line determines how products, operators, and machinery interact across each phase of the process.

An efficient layout has a direct and measurable impact on overall line performance. Effective planning therefore requires a multidisciplinary approach that integrates technical engineering constraints, hygiene and safety standards, and foresight for future scalability. Each stage, from filling to palletizing, must be engineered as part of a seamless, coordinated system, free from operational friction.

Co.Mac., a global leader in the design of filling and packaging lines for kegs, cans, and bottles, develops tailored solutions for both new installations and revamping projects.

In this article, we explore the key principles behind industrial layout design. We’ll cover production space mapping, process flow optimization and production time reduction, offering technical guidance and best practices for each phase.

Mapping the production environment

Mapping the production environment is the foundational step in designing an effective layout for a beverage plant. This process involves a thorough analysis of both structural and dynamic factors, such as architectural limitations, internal logistics, regulatory constraints, and maintenance pathways.

Accurate site assessments enable engineers to define critical spatial parameters from the outset, including inter-machine safety clearances, operational access corridors, loading/unloading areas, and zones for intermediate accumulation. It is also essential to allocate space for future expansions or process upgrades.

To achieve this, 3D CAD platforms and simulation tools are employed to virtually model the entire plant, enabling early detection of bottlenecks and maximizing space utilization.

Insight: Compliance with sanitary design principles is non-negotiable in beverage environments. That’s why AISI 304 or 316 stainless steel is widely used, these materials are corrosion-resistant and suitable for high-cleanliness zones. Human-machine interaction also plays a crucial role in layout development. Each workstation must be accessible, safe, and ergonomic to facilitate both daily operations and technical interventions.

Practical tip: Design modular spaces from the start, using plug-and-play logic to simplify future upgrades. Utility infrastructure, electrical panels, cable trays, access points, must be installed with accessibility and inspectability in mind, ensuring streamlined technical audits and maintenance.

All Co.Mac. layouts are documented according to international industrial standards, ensuring traceability, replicability, and long-term maintainability.

Optimizing Product Flow

The next stage in layout development is optimizing the product flow along the line. The goal is to streamline the process, eliminating unnecessary transitions and preventing crossovers or delays between production areas. A streamlined, logically sequenced flow is essential to avoid inefficiencies and ensure hygienic continuity across all key phases: depalletizing, rinsing, filling, capping, labeling, quality control and palletizing.

Practical tip: Avoid cross-flow layouts, which may compromise safety or increase contamination risks. Where appropriate, include buffer zones in critical areas to reduce process waste and minimize downtime.

Insight: Does the container type or beverage influence the layout? Absolutely.

Kegs require robust conveyors, integrated washing stations, and ample space for palletizing;

Cans, being lightweight but unstable, demand low-friction belts and generous buffer areas to manage micro-stoppages; Glass or PET bottles require guided transport, orientation systems, and carefully controlled speeds to avoid breakage or accumulation.

The beverage itself also dictates layout requirements: Carbonated beverages (e.g., beer, soft drinks) require isobaric filling systems with CO₂ management to maintain product integrity. Juices and oxygen-sensitive drinks demand controlled environments, sterilization tunnels, or hot-fill systems. Still water can be processed at higher speeds with simpler equipment.

Co.Mac. configures modular conveyors, roller, chain, or belt, tailored to the container and desired throughput. Layout shapes (linear, L-shaped, or U-shaped) are custom-designed to suit available space, production volume, and hygiene requirements.

Reducing Production Time

Minimizing production time is a primary goal in layout engineering.

Modern lines are designed to reduce transition delays between machines, automate format changes, and streamline CIP (Cleaning-In-Place) cycles. Intelligent conveyor systems, high-efficiency drive units and integrated PLC/SCADA architectures work in synchrony to maximize output.

Practical tip: During layout planning, it is essential to map the cycle times of each machine and proactively identify potential bottlenecks. Even high-performance machines can slow down the entire line if not properly balanced within the system.

To maintain full operational visibility in real time, proprietary software can be developed to monitor speed, scrap rate, micro-stoppages, and energy consumption. These insights feed into a continuous improvement loop, supporting predictive maintenance and enhancing operational efficiency.

Additional components such as high-efficiency gearmotors and automatic lubrication systems help reduce mechanical wear and ensure long-term performance.

Pro tip: Include a dedicated technical area for spare parts management and routine maintenance. Designing the layout with maintenance in mind significantly reduces unplanned downtime and improves plant safety.

Thanks to their modular architecture, Co.Mac. layouts can be rapidly expanded or reconfigured without the need for invasive structural interventions.

Conclusion

Developing a high-performance line layout demands field-proven expertise, deep technical knowledge, and the flexibility to adapt to varying plant scales and production complexities.

By partnering with a specialized provider like Co.Mac., you can optimize every phase of the process, from initial site mapping to full line commissioning, ensuring scalable, reliable, and fully customized solutions.

Are you interested in learning more about product movement in beverage lines?

We’ve dedicated an article to keg transport systems, complete with real-world examples and technical guidelines you can put into practice immediately.