Cleaning beer kegs: the importance of this process

Cleaning beer kegs is essential to ensure the utmost hygiene and quality of the product. That’s why those who work in this industry can’t do without these machines, for both the internal and external washing of kegs. Let’s then focus today on external washing: which is the best keg external washer for optimal results? Much details in this article.

In this article:

- Why is it crucial to properly wash and clean the keg

- Difference between internal and external keg cleaning

- What is a keg washer

- Comac solutions for external keg cleaning

Why is it crucial to properly wash and clean the keg

When it comes to beer production, every little detail matters. From ingredient selection to processing, and packaging, each stage of the process is part of achieving an excellent end result. Specifically, if kegs are your container of choice, there’s an often-overlooked aspect that plays a pivotal role in producing high-quality beer: cleanliness.

Thorough cleaning of beer kegs is crucial to:

- Ensure the beer maintains its flavor and quality

- Prevent cross-contamination. Beer is sensitive to any external contamination, and even minor traces of bacteria or other contaminants can spoil an entire batch. Therefore, meticulous cleaning of kegs reduces the risk of contamination, ensuring every beer produced is safe to consume.

Difference between internal and external keg cleaning

Another essential aspect worth considering is the difference between the internal and external cleaning of a keg:

- Internal cleaning focuses on removing any beer residues, bacteria, or contaminants inside the keg. This process is vital to guarantee the dispensed beer is of high quality and safe to drink.

- External cleaning concerns removing any contamination or dirt present on the keg’s external surface.

But how to be sure that beer kegs have been thoroughly cleaned? With the right tools, of course.

As far as external washing is concerned, professionally speaking, the best solution is undoubtedly using a keg washer.

What is a keg washer

A keg washer is a machine specifically conceived to guarantee efficient and effective external cleaning of beer kegs.

These machines are engineered to handle kegs of various sizes, cleaning them externally by removing different types of residues and dirt. Typically, the cleaning process involves washing with hot water and specific detergents to eliminate every trace of dirt. After washing, the kegs are thoroughly rinsed to ensure no residues from the cleaning solutions remain.

The use of these machines offers several benefits:

- Efficiency: a keg washer can clean many kegs in a short time. This is why it’s the perfect solution for industrial production that needs to maintain high productivity levels.

- Uniform cleaning: keg washers ensure consistent cleaning of the keg’s external surface.

- Time and labor-saving: by eliminating manual cleaning, keg washers save precious time and human resources.

- Water and detergent reduction: compared to manual washing, an automated machine reduces water and detergent consumption, optimizing their use.

Check out Comac keg lines and discover what we can offer you!

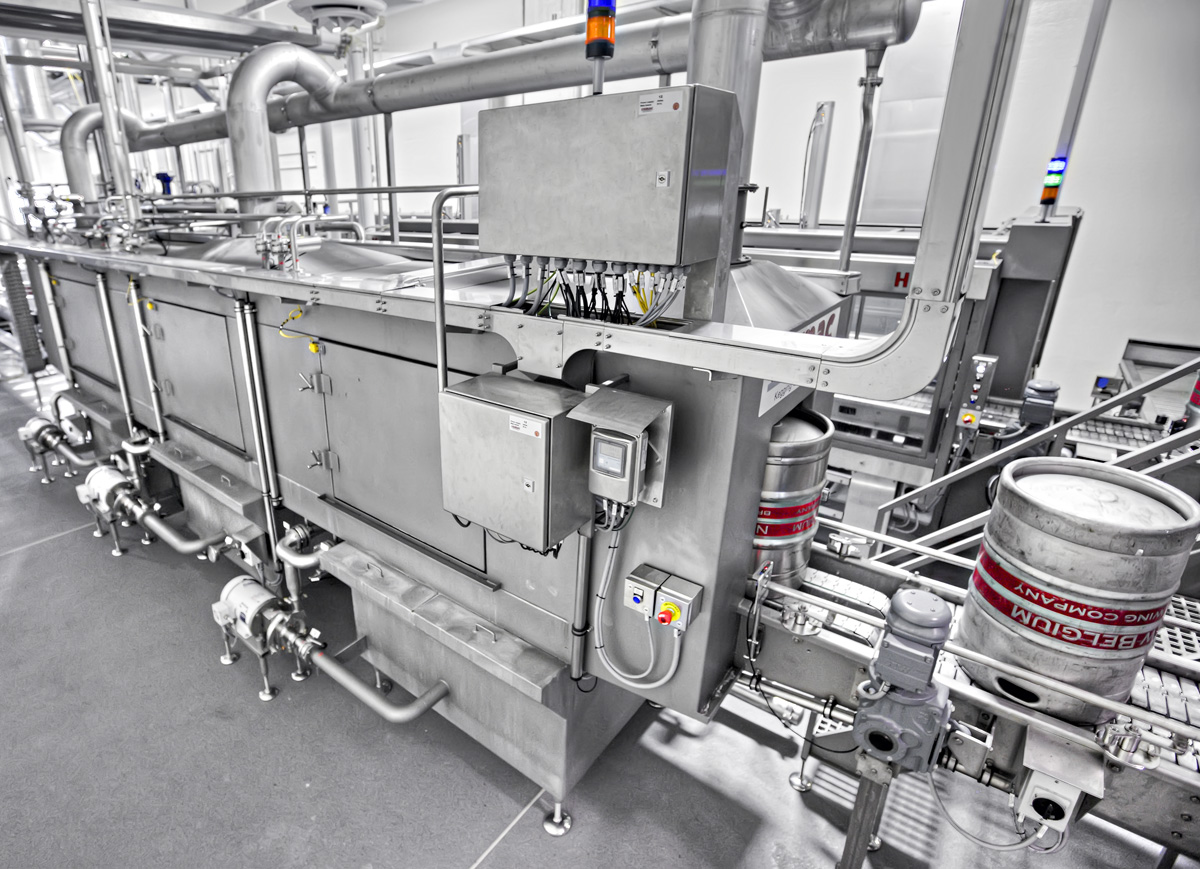

Comac solutions for external keg cleaning

Comac offers a variety of external keg washers designed to cater to different cleaning demands during the production process. These machines vary in terms of size and functionality to match the production line’s speed and the type of cleaning required. They are capable of washing from 30 to over 1,000 kegs per hour:

- Our most compact keg washer is 2 meters long, including a single section and one track. It’s ideal for simple water washing, which can be either hot or recycled.

- We also offer another available option which can be 3 or 4 meters long. It’s designed to perform a first pre-washing with recycled water, a washing with a caustic solution to remove the most persistent dirt and the ink-jet code, and a final rinse with clean water.

In the case of high-capacity production lines, it’s possible to opt for a dual-track keg washer to further increase cleaning capacity.

For high-capacity production lines, you can also opt for a dual-track keg washer to further increase cleaning capacity.

The benefits of these machines include:

- Outstanding performance in external keg cleaning

- Easy and cost-effective maintenance

- Quick changeover

- Significant water consumption saving

- For high-capacity lines, an option to have a separate skid onto which pumps, valves, heat exchangers, etc., are installed to simplify cleaning and maintenance tasks.

If your brewery has specific requirements related to cleaning kegs, Comac is ready to help you create a tailored project. Our experts will work closely with you to design customized plants that meet all your washing requirements.

Your beer deserves only the best, and Comac knows it!