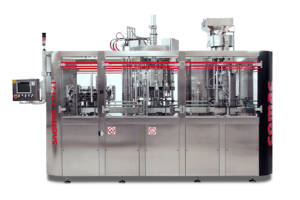

Carbonated soft drinks are usually sold in cans and bottles. Comac is specialized in the realization of different types of carbonated soft drink filling machine, according to the type of container of the beverage.

In this page we will discover some models of carbonated soft drinks filling machines offered by Comac, in particular for cans and bottles.

Carbonated soft drink filling machine: cans

Comac produces automatic systems for the processing and packaging of canned carbonated soft drinks of any size. They are made of aluminum, steel and tinplate and can be customized according to customer requirements.

These system are divided into two categories, according to production capacity:

- for production up to 3,000 cans per hour

- for production up to 12,000 cans per hour

Let’s discover some models.

Pegasus 8-1 V2

Pegasus 8-1 V2 is a carbonated soft drink filling machine able to fill up to 3,000 CPH. It is designed to flush cans with CO2 or other inert gas, fill them with product and finally seam the lids.It is a perfect solution for medium/low capacity lines.

Microbrew 20-4

Microbrew 20-4 is a carbonated soft drink filling machine able to fill up to 12,000 CPH. It is one of the top-seller compact solutions for the craft micro-brewing market, in fact it is especially designed to provide premium equipment to small & medium-sized breweries.

Discover more about our can lines!

Carbonated soft drink filling machine: bottles

Comac also offers automatic bottling machines for processing and packaging bottled carbonated soft drinks of any size. The fillers are designed for the treatment of standard glass bottles, but can also be suitable for the treatment of bottles with special shapes.

All these filling machines can be customized according to customers’ requirements.

Comac’s bottle filling machine can be divided into two categories, according to production capacity:

- bottle filling machines up to 6,000 BPH

- bottle filling machines over 6,000 BPH

Let’s discover some models.

Sagitta 12-12-1 P

Sagitta 12-12-1 P is a carbonated soft drink filling machine able to fill up to 6,000 BPH. It is based on back-pressure filling technology and is designed to rinse the bottles with water or other disinfectant solutions, fill them with product and finally cap them.

Master PET

Master PET is a carbonated soft drink filling machine able to fill up to 70,000 BPH so it is perfect for medium/high capacity lines.

This machine offers the possibility of filling smooth products under gravity conditions, that means that without pressure, there is no extra waste of co2.

These are just some of our carbonated soft drink filling machines.

If you need further information, our collaborators are here to help you!