Find the best solution for your business

Beer packaging is a crucial process in the production and sale of this beverage. It encompasses not only kegging, canning, or bottling beer but also the design and aesthetic appeal of cans, bottles, and kegs themselves, as well as secondary packaging such as cardboard boxes and paper wraps. Each form of packaging has its own advantages and disadvantages, which impact consumer perception and product shelf life. On this page, we will delve into the reasons behind choosing the most suitable primary packaging type for production and marketing needs, focusing on kegs, cans and bottles.

Kegging

Kegging is the less common process of beer packaging in the B2C market, but it is the most employed when a brewery wants to sell its beer to another industry or business in considerable quantities. The reasons are well known and lie on the need to save space and time in packaging and transportation on high scale. Kegging is considerably faster than bottling and canning; it is cheaper as you have, for example, to sanitize one keg instead of many bottles, using a proper keg washing machine.

Discover Co.Mac. solutions for beer kegging:

Canning

Canning is a very common solution in beer packaging. Many big industries in the brewery field have chosen canning to pack their beers, sometimes paired with bottling as well. Cans do not bear the same traditional aura that comes with bottles, but, on the other hand, they appear more innovative, smart, and easy: the perfect choice if you want to pack a beer aimed at a young target.

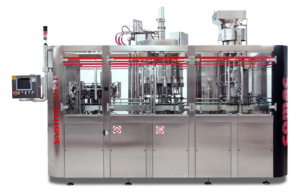

Co.Mac. machines for canning include solutions:

- Canning plants from 3,000 to 12,000 cans per hour

- Canning plants over 12,000 cans per hour in collaboration with the CFT Group

Cans are less expensive than glass bottles, though less resistant to strikes and dents. They fill less space in storage and transportation, bringing considerable savings as far as logistic is concerned.

Bottling

The bottling of beverages can be performed into glass bottles or PET ones. As far as beer packaging is concerned, it is uncommon to find PET bottles, as glass ones are always recommended for a long series of reasons. You will choose glass for bottle packaging if you want to communicate the high quality of your beer, as the glass is the traditional material from which beer bottles have always been made. Glass is hygienic, aesthetically pleasant, natural. It is a must if you own a Microbrewery and you want to appear as an artisan who carries on a long tradition.

Co.Mac. offers a wide range of automatic solutions for beer bottling:

- Bottling plants up to 6,000 bottles per hour

- Bottling plants for over 6,000 bottles per hour in collaboration with the CFT group.

The cons of bottle beer packaging include the weight of the glass, its cost, and the increased difficulty in transporting the bottles, as they take more space to be stored than other containers.

Which beer bottling plant to choose?

Comac develops various beer bottling plants, depending on the type of format and production capacity required. Are you a microbrewery? Do you have wider production requirements? Whether you need to bottle beer in a single format or you need more versatile solutions, Co.Mac. can advise you on the best beer bottling supplies for you needs.