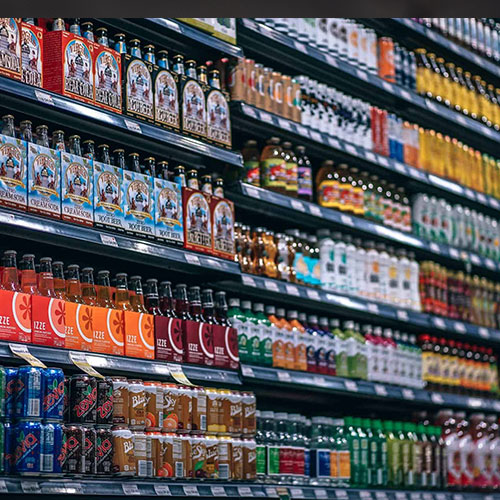

Many solutions to work your drink, with a single point of reference

In more than 30 years of experience around the world, we have been guided by two fundamental concepts: Total Quality and Customer Satisfaction.

We know that our job is to treat your product with the utmost care, so that at the end of the production process it keeps its taste and properties unaltered.

At Co.Mac we are able to do this, whatever the size of your production, the container chosen for filling and the type of beverage chosen.

Also thanks to the synergy with the ATS Corporation group, Co.Mac is at your side at all times, from design to on-site installation of the system: in this way you can save time, speaking with a single point of reference.

And for any technical need, Co.Mac technical assistance 24/24, 6 days a week remains at your disposal, just like our Spare Parts Department.

We guarantee technical assistance 24 hours a day, 6 days a week, even remotely: a certainty that makes our customers from all over the world “rest easy”.