Beverage packaging line support: what to consider

When selecting a partner for a beverage packaging line, the quality of support services can be just as critical as the performance of the equipment itself. Companies seek not only high-performing machines but also comprehensive pre- and post-sales support.

An effective support program goes beyond reactive maintenance, offering continuous monitoring, preventive maintenance, immediate spare parts supply, and technology upgrades aligned with Industry 4.0 standards. Its goal is to preserve line productivity, optimize operational costs, and ensure long-term reliability.

In this context, Co.Mac.—with over thirty years of experience designing packaging lines for beer and beverages—has developed an integrated support service combining technical expertise, digital assistance, and global availability.

The following sections highlight three key aspects to consider when evaluating a support service: response times, spare parts availability and opportunities for revamping to maintain equipment performance and modern standards.

Real-Time support

In the beverage packaging sector, rapid technical response is crucial: even brief machine stoppages can lead to production delays, waste, and unplanned costs, particularly on continuous-operation lines. For this reason, Co.Mac. has developed a multi-tier support service, available Monday through Saturday, covering equipment beyond the warranty period and capable of addressing any need efficiently.

Co.Mac.’s technical support team assists clients throughout the equipment lifecycle, from commissioning to ongoing maintenance. In case of anomalies, technicians provide detailed guidance for inspections or perform remote diagnostics, quickly identifying root causes and corrective actions.

This approach enables real-time monitoring of key machine parameters—such as temperature, pressure, and flow—allowing intervention before minor issues escalate into line stoppages. Co.Mac. organizes support across three time slots to ensure comprehensive coverage:

Daytime service (08:30 – 17:30): online technical support, remote diagnostics when possible, on-site intervention scheduling, and spare parts provision.

Evening service (17:30 – 23:30): exclusive support for Fast Help program clients.

Night service (23:30 – 08:30): priority support for Fast Help users, with reduced response times.

Beyond emergency management, the service includes pre- and post-sales technical consultancy, helping clients select the most suitable solutions and ensure sustained line efficiency.

Tip: to maximize the benefits of remote support, keep machine control software updated and maintain a secure connection to corporate networks. Proactive maintenance based on predictive data analysis can reduce operating costs and significantly extend equipment lifespan.

Interventions and spare parts supply

An effective support service extends beyond technical interventions, encompassing rapid spare parts delivery and preventive maintenance solutions. Co.Mac’s After-Sales Department (Customer Care) is dedicated to supporting clients throughout the equipment lifecycle.

The team manages a centralized inventory of components ready for immediate dispatch, with same-day shipping for orders received by 16:00 CET for stocked items. This ensures fast delivery and full compatibility with operating lines, minimizing unexpected downtime. Detailed information on available parts and supply options is available on the Co.Mac. spare parts page.

Co.Mac. offers preventive and predictive maintenance programs for 4,000, 6,000 and 8,000 hour cycles on can and bottle filling machines, enabling early detection of anomalies before they escalate into failures. Strategic spare parts packages are also available for rapid intervention, ensuring uninterrupted production—even outside standard support hours.

The service also includes technological upgrades and retrofitting, with customized proposals to increase line speed, optimize energy consumption, and update existing equipment in compliance with current regulations. Co.Mac. additionally supports clients with on-site visits, detailed audits and tailored reports for wash and fill cycle analysis and optimization.

Operational note: maintaining a small on-site stock of essential spare parts—such as seals, sensors, or handling components—enables rapid response to minor failures, ensuring production continuity even outside scheduled support hours.

Upgrading and revamping existing equipment

In the beverage packaging sector, evolving product formats, regulations, and production requirements make technological and mechanical updates to existing lines—commonly known as revamping strategic. This approach optimizes performance and extends line lifespan without requiring complete replacement.

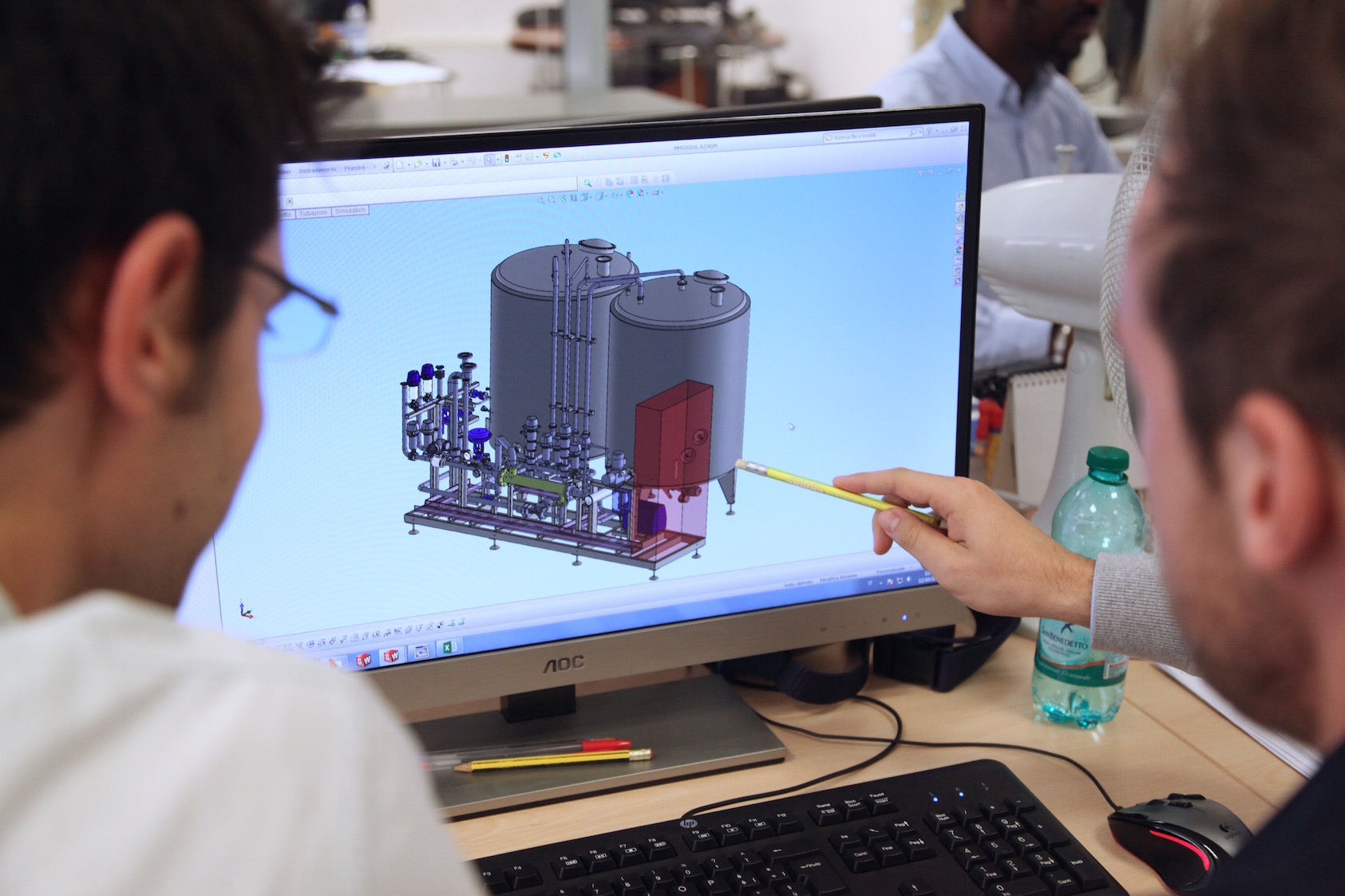

Co.Mac. focuses on integrating new conveyors and machines into existing layouts. Through detailed feasibility studies, the company carries out full-line revamping, updating lines to comply with regulations and client production needs. This includes interventions on specific sections such as conveyors, fillers, or tunnels as well as full-line upgrades, with tailored designs to optimize space, flow, and functionality.

The Co.Mac. revamping process includes:

- Technical analysis and feasibility study: evaluating production needs, available space, and current equipment performance.

- Tailored design: creating customized solutions with detailed layouts and complete technical specifications.

- Implementation and integration: installing new components, control systems, and conveyors, ensuring compatibility with existing lines while optimizing efficiency and safety.

The result is an updated, more flexible, and reliable line capable of meeting current and future production demands. Revamping also improves flow management, reduces downtime, and optimizes plant space utilization.

Technical tip: consider revamping when equipment shows signs of obsolescence, difficulties integrating new formats, or requires increased production capacity. A detailed preliminary analysis allows for a customized upgrade plan, balancing investment, return, and production continuity.

Conclusion

Choosing a reliable partner like Co.Mac. ensures access to a comprehensive service covering all phases of the equipment lifecycle from daily maintenance and original spare parts supply to revamping and technological upgrades of existing lines.

To learn how to optimize the efficiency of your beverage packaging line or receive dedicated technical support, contact the Co.Mac. team via the official website and find the solution best suited to your needs.